INDUSTRIAL SOLUTIONS

Listen beyond the noise

Most industrial facilities rely on monitoring systems to prevent downtime and maintain production. These systems replicate the senses of maintenance personnel—yet hearing is often overlooked. But what if failures are only indicated by sound?

Traditionally, experienced employees have walked the factory floor, listening for subtle changes in machinery noise. However, human hearing is inconsistent. Perception varies between individuals, attentiveness fluctuates, and noisy environments make detection difficult. Moreover, acoustic expertise is intuitive and hard to transfer—one person’s finely tuned ear cannot be easily replicated or taught.

By integrating automated sound monitoring, you eliminate individual bias, enhance safety, and close a critical gap in existing systems. Digitalizing human hearing ensures that all senses contribute to maintenance, allowing you to detect anomalies, track deviations over time, and, most importantly, understand why they happen.

Try it for yourself

Try our industrial array simulator, illustrating the functionality and benefits of a microphone array in an industrial environment. Swap between the array and the microphone, and drag the beam around to hear the different deviations in the facility.

USE CASES

THE PRODUCT

More Than a Microphone - How we provide acoustic insight

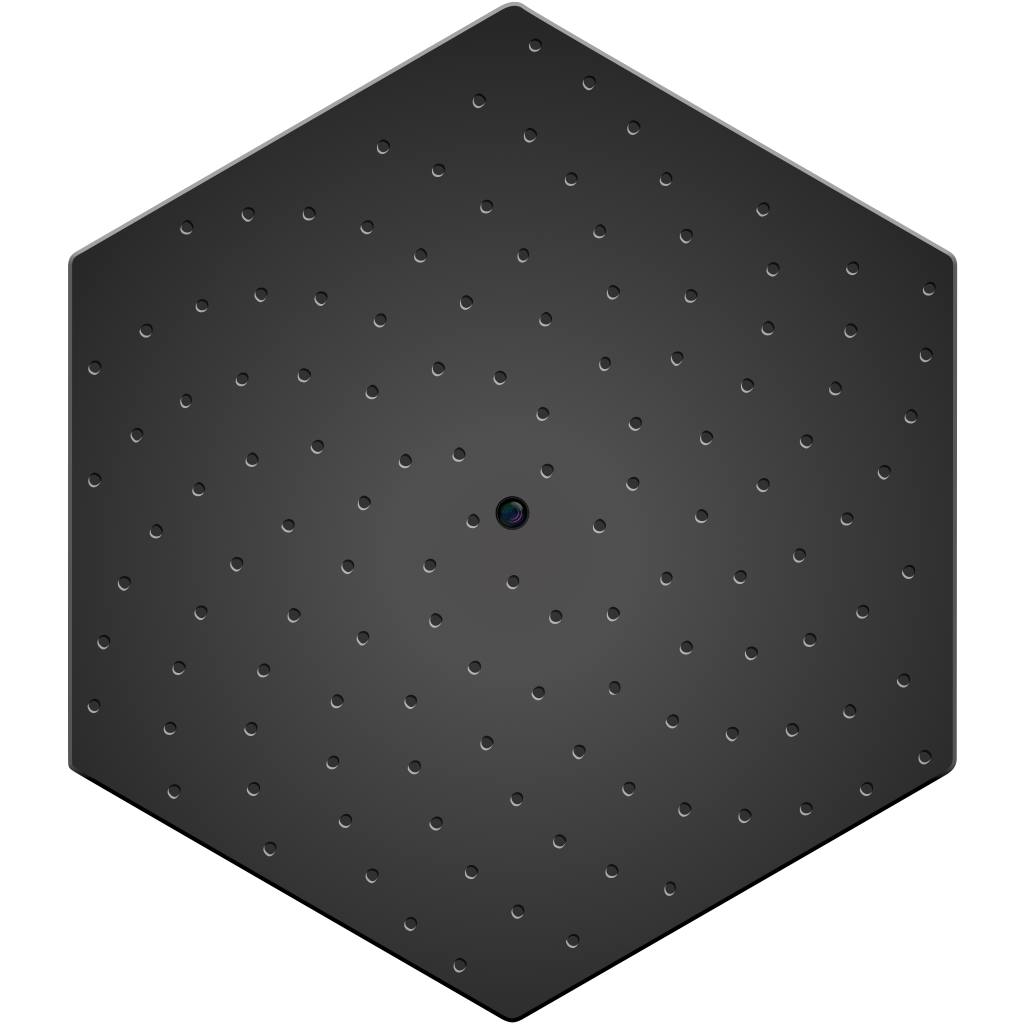

The Squarehead microphone array combines an optical video camera with over a hundred acoustic microphones to deliver precise sound capture and analysis. Unlike single microphones that pick up sound indiscriminately, our array isolates specific sources while suppressing background noise—a capability we call superhearing.

With superhearing, a single microphone array can monitor multiple machine areas simultaneously from a safe distance. By integrating directional audio with video, users can visualize, localize, and listen to selected sound sources, providing a powerful tool for proactive maintenance.

But capturing sound is just the start—our system analyzes audio in real time, extracting key features and transforming raw data into actionable insights. These feature streams are available as time-series data via an industrial protocol, ensuring seamless integration with existing monitoring systems.

Operating on a client-server model, the array runs an “array server” software accessible via a web client or APIs. All signals are processed on edge for real-time performance without relying on external computing resources.

FEATURES

Remote monitoring

Automatic detection

Rich and flexible API

Multiple monitoring points from the same array

Feature streaming

Passive

SPECS AT A GLANCE

Material: Aluminum

Storage: 120 GB SSD

Dimensions: 415x54x475mm (16.3x2.1x18.7in)

Operating temperature range: -20°C to 70°C

Communication standard: OPC-UA

INTERESTED IN A CHAT ABOUT HOW WE CAN HELP YOU FIND THE RIGHT SOLUTION FOR YOUR NEEDS?