Acoustic Monitoring in Lifecycle and Fatigue Testing

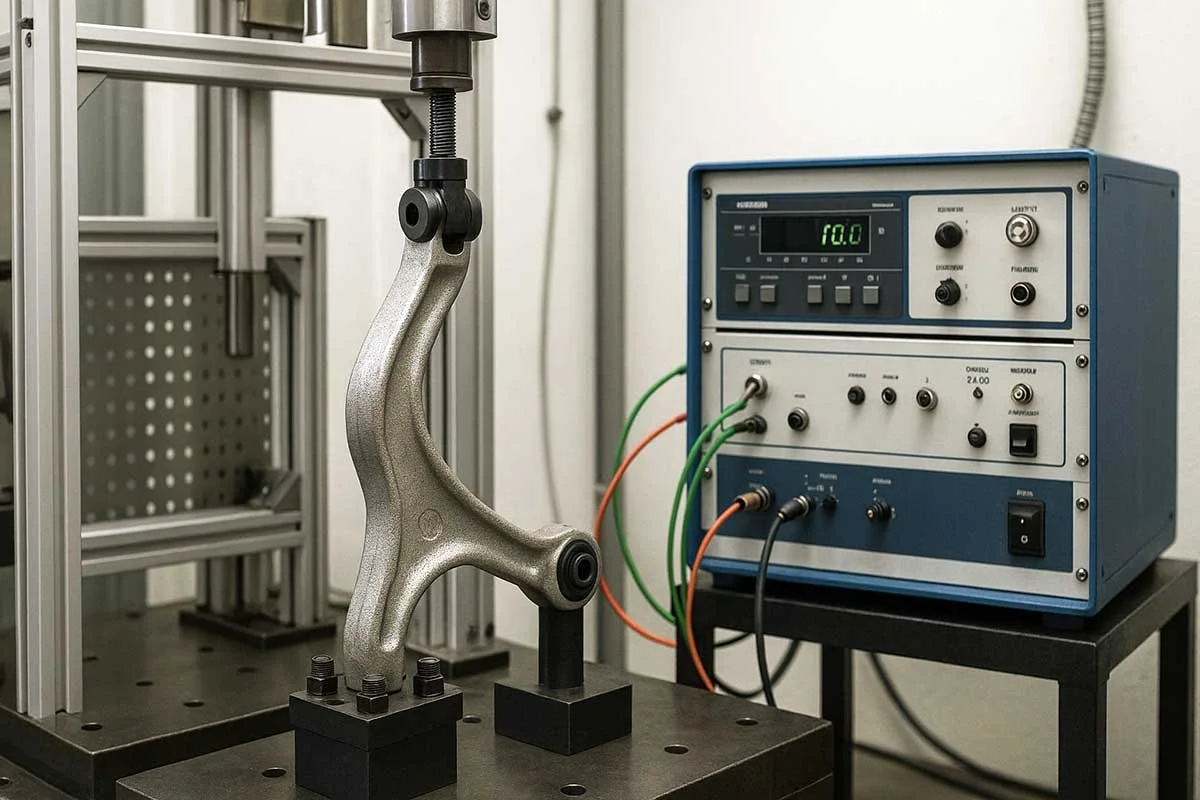

In industries where reliability is non-negotiable, like in automotive, aerospace, mechanical engineering, and consumer products, fatigue testing plays a crucial role. Also known as lifecycle testing, it subjects materials and components to repetitive loading until failure, revealing vital insights into durability, structural limits, and product lifespan.

What’s Missing in Traditional Methods

Conventional fatigue tests are endurance marathons: thousands, sometimes millions, of stress cycles over extended periods. Operators monitor for failure points, but traditional tools struggle to detect the earliest signs of material or machine degradation. Micro-cracks and internal weaknesses often go unnoticed until it’s too late, and identifying exactly when and where a crack began typically involves stopping the test—disrupting continuity and adding complexity.

Acoustic Precision

Squarehead Technology offers a new approach. By applying acoustic monitoring through advanced microphone arrays and beamforming algorithms, subtle shifts in sound signatures are captured in real time. These shifts—barely audible, yet acoustically distinct—signal the onset of wear, fatigue, or structural damage well before they surface visually or mechanically.

What This Makes Possible

Early Detection, Done Right: Minute changes in the acoustic profile can reveal the very first signs of fatigue. This makes it possible to act before minor issues grow into structural failures.

Continuous, High-Resolution Insights: Unlike sporadic measurements, Squarehead’s system records and analyzes the full acoustic stream throughout the test. Engineers can now map how a material evolves under stress—with much finer resolution.

Failure, Documented in Sound and Vision: The system captures high-quality, synchronized audio and video of the failure moment. This makes post-test analysis far more exact, providing both context and clarity into failure modes.

A Smarter Way to Understand Fatigue

By adding advanced acoustic analysis to fatigue testing, manufacturers gain a deeper understanding of how and when materials fail. It’s a step forward not just in detection, but in the precision and confidence with which that detection is made.

LIFECYCLE & FATIGUE TESTING

Why it matters

Integrating Squarehead’s acoustic monitoring into fatigue testing offers something traditional systems can’t: real-time awareness of degradation as it happens. For companies building safety-critical or high-durability products, this translates into better designs, safer outcomes, and a stronger command over lifecycle performance.

INTERESTED TO SEE HOW WE CAN IMPROVE YOUR ACOUSTIC SITUATIONAL AWARENESS?

CONTACT OUR INDUSTRIAL TEAM FOR MORE INFORMATION.